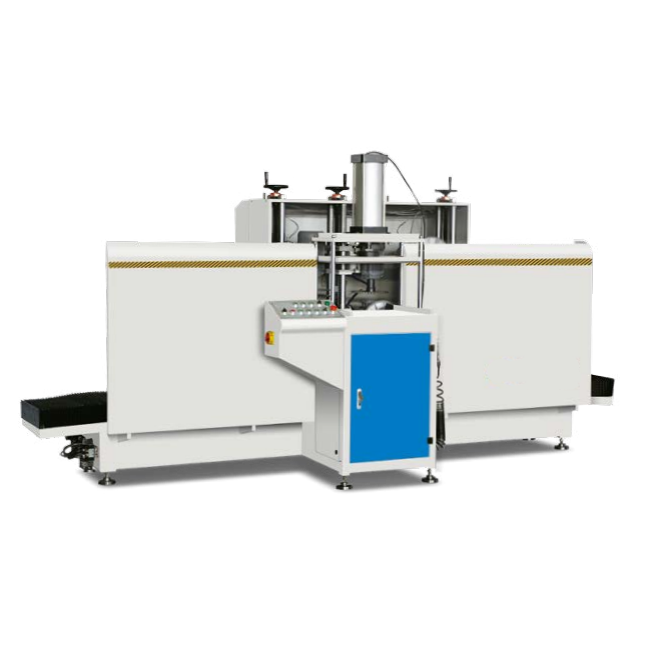

Product Description

-

This machine features a stationary material fixture with moving cutting tools, enabling efficient forming processing for long profiles in high-volume and multi-batch production.

-

Six sets of modular cutters can be flexibly combined to achieve arbitrary dimensions based on user requirements. Two of these cutter sets are adjustable within a 180° range for versatile machining angles.

-

A single pass completes the milling of required tenon/mortise dimensions on the profile end face. Customized tool thicknesses are available to meet specific customer needs for unique tenon/mortise specifications.

-

Equipped with a worm gear reducer to ensure smooth and stable tool feed, guaranteeing high precision in profile processing dimensions.

Product Parameters

| Power supply | 380V 50Hz |

| Total motor power | 13.2kw / 13.2kw (six sets) |

| Motor rotary speed | 2800r/min |

| Working air pressure | 0.5 - 0.8MPa |

| Feeding motor | 1.1kw |

| Main spindle diameter | φ32mm |

| Maximum cutting depth | 6 pieces φ250 blades, 4 pieces 14” saw blades |

| Tool feeding travel | 1650mm |

| Worktable size | 510 x 480mm |

| Tool adjustment travel | Horizontal 80mm, Vertical 280mm |

| Overall dimension | 4000 x 1340 x 1965mm |

| Weight | about 2000kg |

FAQ