Product Description

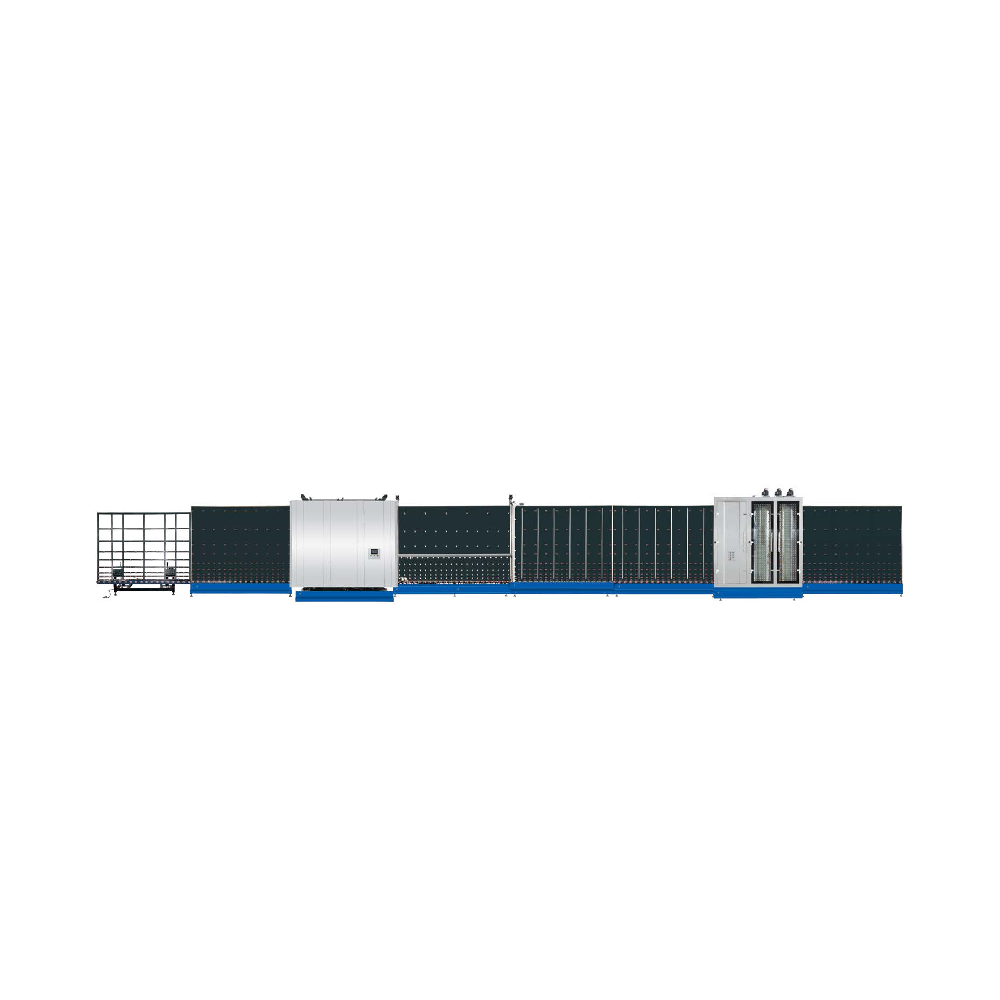

Our insulating glass production line is engineered for manufacturing high-quality insulating glass units (IGUs) with the following features and advantages:

-

Comprehensive Configuration: Comprises a high-speed glass washing machine and an automatic glass assembly machine as standard, with optional equipment including glass cutting machines, polishing machines, lifters, automatic sealant applicators, spacer bending machines, sealant dispensing machines, and molecular sieve fillers.

-

European Engineering Design: Incorporates intelligent and user-friendly operation principles for seamless productivity.

-

Premium Components: Utilizes world-renowned critical parts to ensure exceptional stability and extended service life.

-

Wide Glass Compatibility: Designed for processing reflective glass, low-E glass, tempered glass, and laminated glass with high precision.

-

Scalable Production Capacity: Offers multiple models and customizable solutions, achieving a daily output of up to 1,000 units.

-

Versatile Application: Supports double-pane, triple-pane, step-shaped, and custom-shaped insulating glass production.

-

Automatic Argon Gas Filling: Integrated argon infusion during assembly for enhanced thermal insulation performance.

-

Advanced Control System: Equipped with PLC and touchscreen interface for precise adjustments and monitoring.

Product Parameters

| Specification | |

|---|---|

| Input Frequency | 50Hz 380V |

| Input Power | 21 kW |

| Output Frequency | 0.5 ~ 0.8 times |

| Maximum Rotational Speed | 2500 ~ 3500 RPM |

| Rated Rotational Speed | 280 ~ 450 RPM |

| Processing Range | 3 ~ 18 tons |

| Operating Temperature | 8-45°C/minutes |

| Output | 25300*2000 * 3700 tons |

| Weight | 6000 tons |

FAQ

Q1: Are you a manufacturer?A:Yes, we are a professional manufacturer with our own factory. You are welcome to visit us anytime.

Q2: Is your quotation based on the retail price for a single unit or the agent price?

A: Actually, the price is the same whether you buy just one unit or become an agent. But here’s the good part—if you’re an agent, we won’t sell in your designated territory at all. So even though the price is the same, you get full protection and exclusive opportunities in your market.

Q3: What are your payment terms?

A: We generally require staged payments: a 20% deposit upon order confirmation to secure production, and the remaining 80% balance should be settled before shipment.

Q4: Can I watch a real video of the machine before purchasing?

A: Absolutely! We provide demonstration videos, authentic customer feedback, and can arrange a live video call to show you the machine in actual operation.

Q5: What is your warranty policy?

A: Our warranty policy is as follows: Basic Warranty:

A:One-year warranty for the whole machine.

B:Two-year warranty for core components (excluding consumables/spare parts).

After the warranty period: customers can purchase consumables and spare parts at distributor prices for life, and receive repair guidance via video or email.

Q6: Do I need to pay import taxes? How about the customs clearance process?

A: Import taxes depend on the regulations of your country/region. Normally, you need to pay local duties/taxes by yourself. However, we will prepare all necessary documents and assist you during the customs clearance process.

Q7: What is your production and delivery time?

A: For standard models, delivery usually takes 3–15 working days. For customized equipment, delivery usually takes 10–35 working days.

Q8: What kind of operation guidance do you provide after purchasing the machine?

A:English manuals and video tutorials.

B:One-on-one online training.

C:Option to dispatch professional engineers for on-site installation, commissioning, and training.

Q9: Can you deliver to my country? How much is the shipping cost?

A: Yes, we provide worldwide delivery service. Please provide your city and country/region, and we will recommend the best shipping method (by sea, air, or door-to-door) and offer you an accurate freight quotation.

Q10: Can I request customized equipment?

A: Of course. We can meet diverse customer needs. You can customize machine size, functions, materials, voltage, color, logo, and even the complete production line layout.